In the trade settlement and process measurement management of industries such as petroleum, chemical engineering, and urban gas, flow totalizers are core equipment for realizing parameter collection and accurate statistics of fluid media. The GTXSJ96 Flow Totalizer is based on an ARM microprocessor, paired with various flow transmitters and sensors. It adapts to different fluid characteristics through multiple flow mathematical models, while integrating full-process functions such as data collection, display, control, and remote transmission, making it an efficient solution for fluid metering in industrial scenarios.

1. Core Product Positioning and Application Scenarios

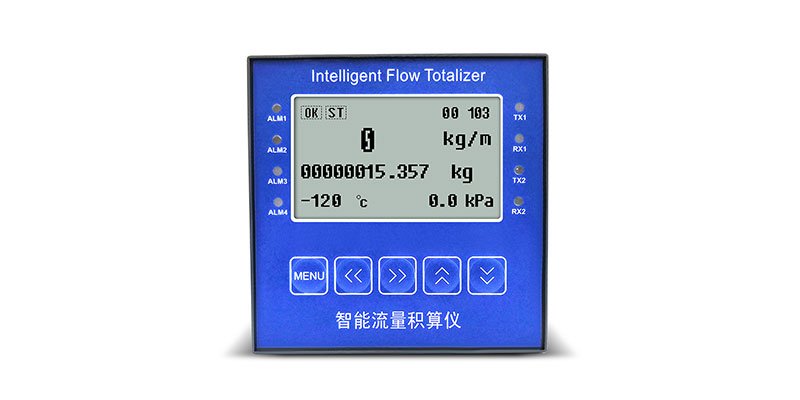

The GTXSJ96 is a precision intelligent flow totalizer. Its core logic is to use the computing power of the ARM processor, combined with the collection of signals such as flow, temperature, and pressure, and use exclusive mathematical models to complete accurate flow calculation of different fluid media. Its functions cover on-site parameter collection, real-time data display, automatic control output, remote communication transmission, report printing, etc., and can independently form a digital collection and monitoring system.

Currently, this device has been widely used in industries such as petroleum, chemical engineering, metallurgy, power, light industry, medicine, and urban gas. It is suitable for both single-point process measurement management and integration into enterprise-level metering networks, supporting cross-scenario trade settlement, data traceability, and process control.

2. Core Technical Parameters and Functional Configuration

2.1 Basic Hardware and Interface Specifications

- Structure and Installation: The external dimensions are 9696mm, adapting to the 9292mm opening size, which meets the standardized installation requirements of industrial instruments;

- Channels and Communication: Supports signal access for 3 types of channels (flow, temperature, pressure). The communication methods include RS485 bus communication and USB export functions, meeting the needs of real-time data transmission and offline report storage;

- Power Supply and Power Consumption: Adopts conventional power supply methods of AC 220VAC and DC 24VDC, and is equipped with a 12V, 20AH backup power supply, which can realize 72 hours of continuous power supply; the total power consumption of the whole machine is ≤10W, which is suitable for the energy consumption standards of industrial scenarios.

2.2 Signal Input and Output Capabilities

- Signal Input:

Supports multi-type signal access, including analog inputs such as thermocouples (K, E, B and other models, customizable), thermal resistors (Pt100, Pt1000, need to be specified before ordering), DC current (0-10mA, 4-20mA); it is also compatible with pulse input (waveforms include square wave, triangular wave), switch input (amplitude ≥5V), frequency input (0-10kHz, customizable), and can adapt to most industrial sensors and transmitters;

- Signal Output:

The output functions cover analog quantity (0-10mA), communication interfaces (RS232, RS485, Ethernet), relay switches (AC220V/DC24V), and feed output (DC24V, DC12V), which can directly drive external actuators and connect to upper computer systems to meet control and linkage needs.

2.3 Measurement, Display and Control Capabilities

- Measurement Accuracy and Range: The measurement accuracy reaches 0.2%FS±1d or 0.5%FS±1d, and the frequency measurement range is 0-10kHz; the flow measurement value supports 999999-999999 (28 bits), and the cumulative flow range is 0-99999999.9999, which can cover the needs from small and medium flow to large-scale fluid metering;

- Display and Control: Supports simultaneous display of multiple parameters such as flow, temperature, pressure, and density. At the same time, it can configure the upper and lower limit control (alarm) output of the relay, has LCD/LED output indication function, and can expand up to 2 relay control (alarm) outputs to realize real-time early warning of parameter abnormalities;

- Print Function: Connect to the printer through the RS232 interface, support timing printing of the upper and lower limits of flow, temperature, and pressure (up to 8 times a day), meeting the needs of data archiving and process traceability.

2.4 Environmental Adaptability and Protection Mechanisms

- Working Environment: Adapt to industrial scenarios with temperature -20~60℃ and humidity ≤85%RH, and have the characteristics of resistance to strong corrosive gases, which can be applied to harsh environments such as chemical industry;

- Protection Functions: Data can be retained for more than 20 years after the power supply is turned off, and it will automatically reset when the power is insufficient; the device supports automatic reset of work abnormalities (watchdog) and is equipped with a self-recovery fuse, which improves the stability and data security of long-term operation.

3. Product Value Summary

The core advantages of the GTXSJ96 Flow Totalizer lie in “multi-signal adaptation + high-precision calculation + full-function integration”: it is compatible with most industrial sensors through rich signal interfaces, ensures the accuracy of flow calculation with ARM processors and exclusive mathematical models, and integrates functions such as control, communication, printing, and backup power supply, taking into account the practicality and reliability of industrial scenarios.

In terms of scenario adaptability, its standardized installation size, multi-power supply methods, and harsh environment-resistant design can cover conventional industrial points and complex working conditions; the communication combination of RS485+USB and timing printing functions also meet the management needs of modern industry for data transmission and archiving, making it a cost-effective terminal device in the field of industrial fluid metering.